Location: Dyeing & finishing plant in Taiwan

Time: 10,May, 2016

Capacity: 10Mt/Day consecutive operation

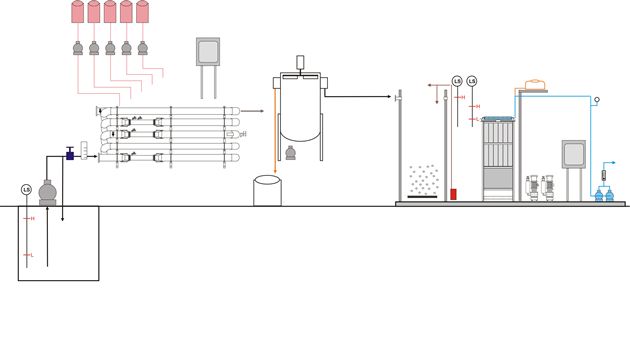

Revitalize Hundred Million Knitting Co. dyes clothes of Polyester, Nylon and T/C. In this test, the machine runs consecutively for 24 hours; dealing with 10 tons of segregated highly polluted wastewater every day.

So far, the testing machine has run for 1 year and 2 months, well performing negative pressure and flux of the membrane. The treated water is below the emission standards of industrial zones. The water is also taken to do color matching of red, yellow, turquoise blue, which, after being examined by the computer, are almost undifferentiated from the standard dyeing cloth samples. This reveals that, after being treated through our testing machine, the highly polluted wastewater complies with the reclamation standards.

A Dyeing and finishing factory’s effluents vary according to different products. Our company’s model machine may be moved to the client’s factory to display its treatment effect on the wastewater extracted from the equalizing basin.

Time: 10,May, 2016

Capacity: 10Mt/Day consecutive operation

Revitalize Hundred Million Knitting Co. dyes clothes of Polyester, Nylon and T/C. In this test, the machine runs consecutively for 24 hours; dealing with 10 tons of segregated highly polluted wastewater every day.

So far, the testing machine has run for 1 year and 2 months, well performing negative pressure and flux of the membrane. The treated water is below the emission standards of industrial zones. The water is also taken to do color matching of red, yellow, turquoise blue, which, after being examined by the computer, are almost undifferentiated from the standard dyeing cloth samples. This reveals that, after being treated through our testing machine, the highly polluted wastewater complies with the reclamation standards.

A Dyeing and finishing factory’s effluents vary according to different products. Our company’s model machine may be moved to the client’s factory to display its treatment effect on the wastewater extracted from the equalizing basin.

.jpg)

2.Domestic engineering

Forest Water Sustainability decoloring agent using result in Taiwan

.jpg)

Forest Water Sustainability decoloring agent using result in Taiwan

| Project report- Color Removal in the Cotton Yarn Dyeing Factory-TEX-RAY Industrial Co. | |

| Project target | Tainan TEX-RAY Industrial Co. |

| Fibers | Mainly cotton yarn, T/C |

| Daily water consumption | 2000-2500CMD |

| Sludge yield | 4-6 tons |

| Wastewater treatment process | Bio + chemical + bleaching color removal (complete process, absolute treatment) |

| Project goals | Test the effect of color removal. Plan the equipment. The bleaching method to remove color might be illegal in the future, so a substitute color removal plan is needed. |

| Project content | In order to respond accordingly to various water qualities from different factories, the testing equipment that can directly extract wastewater from equalizing basins to do consecutive color removal treatment is designed. |

| Equipment features | 1.Easy to transport and assemble with good adaptability to most spaces. 2.The wastewater treatment volume can be adjusted to 50-100 CMD to facilitate cost accounting. 3.The packed equipment is weather resistant. |

3.Foreign engineering

Forest Water Sustainability decoloring agent using result in foreign dyeing factory

Forest Water Sustainability decoloring agent using result in foreign dyeing factory

5.TAIWAN Performance

.jpg)

Forest Water Sustainability assists food factories in color removal projects in Taiwan

| Food factory color removal | |

| Project target | Ruifang O O food factory |

| Wastewater treatment process | The color removal equipment of the sewage in the food factory is added, and the special decolorizing agent is effectively controlled to be added to destroy the color structure, so that the bacteria can be easily decomposed to facilitate subsequent biological treatment and improve the sewage treatment effect. |