In the dyeing and finishing industry, there are different producing processes and standards of water according to various kinds of fiber processing. We may modify the wastewater treatment according to our clients’ requirements so as to accomplish wastewater reclamation, and the project princes we offer are of market competitiveness among other unexperienced competitors.

Comparison between traditional decoloration and flotation and Forest Water Sustainability company's system

Traditional ways of decoloration in the dyeing and finishing process is to use PAC+PAM or to add dicyandiamide (DCD) type or formaldehyde (Formalin) type decoloring agents, which may cause secondary environmental pollution, so that the use of the reclaimed water requires additional assessments and tests.

The chemicals adopted in the decoloration process planed by Forest Water Sustainability Co. are inspected to meet the EU regulations and do not pollute the cloth, and the use of the chemicals generates no chemical sludge and reacts quickly. This decoloration and flotation equipment shortens the reaction time by 50%, reduces the space (depending on the field situation) and an estimated 40% to 50% chemical sludge volume, and is highly compatible with the current equipment.

The chemicals adopted in the decoloration process planed by Forest Water Sustainability Co. are inspected to meet the EU regulations and do not pollute the cloth, and the use of the chemicals generates no chemical sludge and reacts quickly. This decoloration and flotation equipment shortens the reaction time by 50%, reduces the space (depending on the field situation) and an estimated 40% to 50% chemical sludge volume, and is highly compatible with the current equipment.

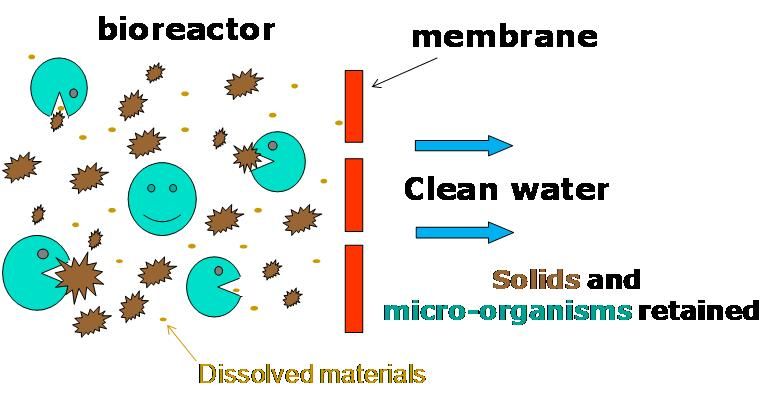

Comparison between the traditional bioreactor and the Forest Water Sustainability company's system

The traditional bioreactor takes 24 to 48 hours to react, occupies large space with low efficiency, and generates sludge in the biological sludge clarifier that makes many organisms flow out in the effluent without valid utilization.

The system planned by Forest Water Sustainability Co. solves the space problem. The organisms are blocked in the bioreactor to improve the efficiency, and it takes only 12 to 24 hours to meet the emission standards, MBR’s SS<5mgL.

The system planned by Forest Water Sustainability Co. solves the space problem. The organisms are blocked in the bioreactor to improve the efficiency, and it takes only 12 to 24 hours to meet the emission standards, MBR’s SS<5mgL.

Forest Water Sustainability Company's wastewater treatment process

Drum Screen:

Prevent fibers, yarn, big particles or foreign materials from clogging and damaging MBR in the wastewater treatment system.

Equalization Tank:Control the flow. Equalize colors, COD, temperatures, pH of the wastewater.

Decoloring:

The dyeing and finishing wastewater contains dyes, which will lead to low quality of reclamation water or fines on the unqualified effluent. Most decoloring agents contain must-not-detectable particles on fibers or environmental toxins like HCHO or DCD, which may be highly residual on the fiber. The decoloring agent designed by our company works well on the commonly used dyes and even fluorescent dyes.

A. Add no-sludge-yield agent. Mix.

B. Damage the dye’s structure and decolor, increasing biodegradation efficiency.

C. Adjust pH from 6 to 8.

D. Decolorize

A. Add no-sludge-yield agent. Mix.

B. Damage the dye’s structure and decolor, increasing biodegradation efficiency.

C. Adjust pH from 6 to 8.

D. Decolorize

The reports of the color removal tests

| Segregation on high concentrated wastewater Decoloration & flotation reclamation water | ||

| Before | After | |

| COD | 1300~1600 | 40~80 |

| Color | above standards | 25~50 |

| ss | above standards | <2.5 |

| pH | 9~10 | 6~8 |

Cooling Tower:

Decrease temperature of the wastewater for biological growth

Flotation:

Remove suspended substances in the wastewater.

Bioreactor:

MBR membrane, whose hole diameter (0.2μm) is smaller than most bacteria, can block microorganism and suspended substances in the bioreactor to make the filtered water SS<30.

Membrane Bioreactor, MBR:

MBR occupies smaller area than the settling basin and retains microorganism in the basin to increase 2 to 3-fold microorganism and therefore improve the biodegradation efficiency.

(1).jpg)